sizing heater

Sizing the heater

The heaters for enclosures are available in different power (from 20 up to 800W) and differ in the presence or absence of a fan to force the expulsion of the heated air and facilitates the reshuffling. To select the right product you need to consider several factor: the place where it will operate, and the climatic conditions and material of the enclosure.

You can define the required power aswhere:

Q = S * C * ΔT

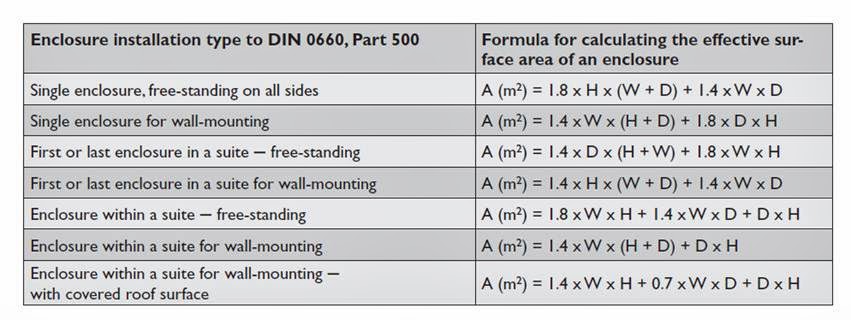

S represents the heat exchange surface of the enclosure, for which in addition to being dependent on the size also varies according to the type of installation (isolated, mounted to a wall or adjacent to other enclosures at the same temperature).

The standard EN 60439-1 describes the method of calculation used to define the “equivalent area”.

C It is the heat exchange coefficient, a value that depends on the material of the electrical panel, and therefore its susceptibility to thermally insulate the electrical components. Some characteristic values of our interest are 12 for aluminum, 5 for steel and 3.5 for polyester.

ΔT Indicates the difference between the desired temperature inside and the outside.

These calculations are very useful for a first approximation of sizing, which must be analyzed on a case by case basis given the large number of parameters (especially environmental) that affect the power required.

The presence of the fan that forces the air passing through the heater greatly increases the heat exchange between anti-condensation and the electrical panel, for this reason it is necessary in the enclosures with large volumes of air inside.

Another parameter that has an important role is the reaction time. When the temperature drops suddenly to prevent the formation of condensation the intervention of the heater must be fast, in this case is indicated the use of a fan operating heater that processes a high volume of air in a short time.

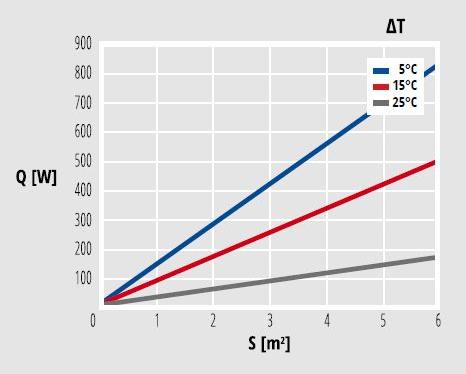

Quick sizing chart for aluminium alloy enclosure